Technical Parameters

Contact us

AB Glue Mixing and Dispensing Machine

Current location:HOME>MG-2600 Full Automatic AB Glue Mixing & Dispensing Machine

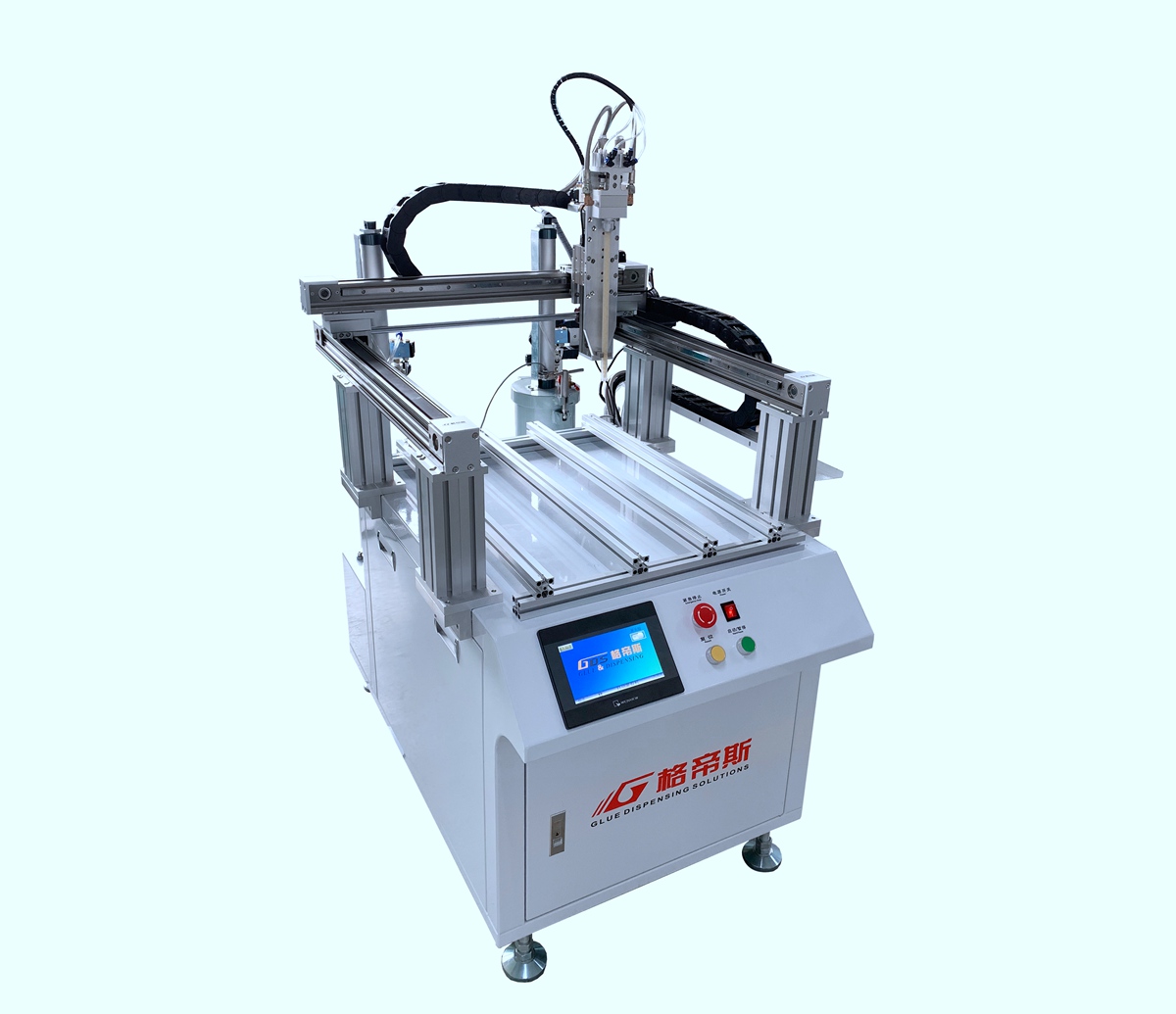

MG-2600 Full Automatic AB Glue Mixing & Dispensing Machine

Principle Descriptionu AB glue are stored in two containers independently. Glue A and B are filled into the mixing pipe separately through precise calculation

- Product introduction

- Technical Parameters

- Video display

Principle Description

u

AB glue are stored in two containers

independently

. Glue A and B are filled into the mixing pipe separately through precise calculation of two metering pumps based on needs. The three-axis mechanical hands drive glue nozzle to conduct rated glue dispensing

by

programmed

instructions

.

Machine Features

u

Full-automatic for all steps :metering, proportioning, mixing, dispensing

…

;

u

Equipped with 2600ml barrel or two 304 stainless steel glue containers for storing glue A and glue B separately to prevent the glue getting dry for longtime no use;

u

The mechanical part of 3-Axis equipped high precision linear motion module, high accurate positioning and repeat positioning;

u

Touch screen UI with hand programming controller, easy to learn and operate;

u

Provide customized fixture and gluing multi-heads for different

work-pieces

.

Technical Parameters

|

Model

|

MG-2600

|

|

|

Working Range

|

400*400*100 mm(

X*Y*Z

)

|

|

|

Moving Speed

|

0~

500mm/sec

|

|

|

Repeat Accuracy

|

±0.02mm

|

|

|

Mixing Proportion

|

100:100~

100:10(1:1~10:1)

|

|

|

Metering Method

|

Precise Gear Pump or

S

crew Pump

|

|

|

Mixing Method

|

Static Mixing

|

|

|

Glue Dispensing Volume

|

0.3~

30 ml/S

|

|

|

Mixing Accuracy

|

±1%

|

|

|

Glue Extrusion Accuracy

|

±1%

|

|

|

Glue Container Capacity

|

30L 304 Stainless Barrel

|

|

|

Glue Viscosity

|

Max≤

20000CPS

|

|

|

Glue Additive Proportion

|

MAX≤

100(Glue):100(Additive)(1:1)

|

|

|

Glue Additive Size

|

Max≤

400tsp

|

|

|

Control Mode

|

PLC+Handhold Teaching Programming Case+Touch Screen

|

|

|

Programming

|

Teaching Programming

|

|

|

Program Capacity

|

At least 100 unit, 4000 points/unit

|

|

|

Transmission Method

|

Steeping Motor+Synchronous Belt+Linear Guide-way

|

|

|

Working Pressure

|

0.5-0.8Mpa

|

|

|

Working Power

|

AC220V 50HZ/2000W(stirring,vacuuming, heating not included)

|

|

|

Working Temperature

|

0-40℃

|

|

|

Working Humidity

|

20-90% no condensation

|

|

|

Dimension

|

70*115*150CMmm(

WxDxH

)

|

|

|

Weight

|

About 100KG

|

|

|

Optional Functions

|

Glue container stirring, pre-heating, vacuum de

gassing

,

self-

cleaning

|

|

Suitable Glue

:

Double-component glue, such as organic silicone, epoxy, PU, acrylate etc.

Applications

:

Small size products with small volume of glue, such as mutual inductor, transformer, power module, photo-voltaic module, automobile head light, daytime running light, negative-ion generator etc.